The stock seat that comes on the Rebel is as comfortable as I could expect for a seat made to fit everybutty. However it isn’t perfectly

designed for me, and I have read about a simple modification that allows the rider to sit further back on the seat without sliding forward. It

consists of removing a steel plate in the padding. To do this, the cover is removed and stapled back in place. I decided that as long as I

was at it, I would add some foam to the existing stuff to add some give. Of course I would have to make a new cover, as the old one would

no longer fit over the new volume of padding. Easy enough. Yeah. I bought an old seat on Ebay. It was well worn and had no cover when I

got it. The first thing I had to do was remove the bracket with the pillion strap. The bolts that secure it are molded into the plastic seat pan

itself, and spun before I could get the nuts loose. I ended up drilling them out from the top, and replacing them. I used stainless steel for

the new hardware. If I ever have to do this again, it should be much easier. The next step was to add the

supplemental padding. I traced the basic shape onto cardboard, and then the foam. Since the original pad was

badly worn around the buttons, I decided to reinforce the worn areas with some leather I had laying around. I

cut and trimmed the foam with an electric knife, and then stuck it all together with aerosol adhesive, and tied it

in cardboard to dry. Note- Gluing the foam on at this point came back to bite me when I tried to mount the

buttons later. They attach via nylon strings through the cover and pad to plastic discs under the pad. I had to

fashion a chisel point on a carbon steel rod, and spin it through the leather after the fact. This is one of several

details I’ll rethink if I do this again. The next step was the scary part. I had to lay out the cover material, and

sew the pieces together. I had a basic concept in mind of how the cover was to be constructed: A single panel

for the top, and a long section to go around the perimeter. I went to a local fabric store and got the materials. A

kind sales lady advised me what sort of cover material to buy, and also sold me a hand held battery operated

sewing gadget that is great for taking up space in a drawer. It was obvious that I would need a real sewing

machine, and at least a few of the requisite skills required to use one.

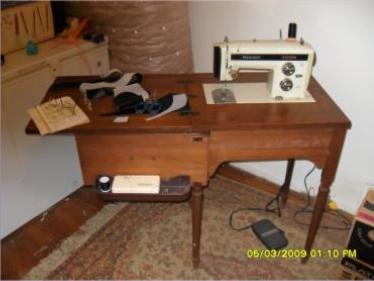

I found a seventies vintage Kenmore sewing machine for forty bucks

on Craig’s list. What followed was a truly humbling experience. I work

on machines for a living, so being unable to get this thing to do a

simple task was beyond frustrating. My grandmother would have

played with it for relaxation; I was just trying to get it to sew an inch

without creating a giant knot of thread. After applying the basic

diagnostic approach, I figured out that there are several things that

have to be dealt with individually before they can work together. Since

I was using heavy thread, I needed a needle with a bigger eye than

any that came with the machine. The tensioner thingie on top, and the

tensioner thingie on the bobbin both had to be adjusted to match the

material, the thread, and each other. It took me more time than I care

to admit to get it tweaked. That part done, I had to figure out how to

join compound curves on two planes while only being able to see

markings on one. An experienced seamstress turned me

on to the obvious solution: Mark where you want the

stitches on both pieces, and trim the excess off at a

uniform distance from the line so you can align the

edges of the material with the nifty lines on the plate the

needle goes through to put the stitches where you want

them. It’s almost like someone else has run into this

puzzle before. But I digress. Back to the process. This is

the instrument in question.

We have achieved détente; I don’t know that we’ll ever

be friends. With the machine set to go, I cut the vinyl

according to the patterns I had traced from my original

seat. Then the simple matter of the actual sewing. This left me with two things to tend to: the

buttons, and stretching it all on to the seat pan. I almost decided to forego the buttons, but I

thought they might help keep the seat from losing shape due to lateral shifting under my weight. I

measured the distance between the buttons, stretched the cover out on the pad, and marked the

locations. I used bamboo skewers to puncture the cover and make a path through the foam for

the nylon cords that hold the buttons in place. This is when I realized I had not made holes in the

leather reinforcement pieces. (see note above). I wanted to make sure that water wasn’t going to

get into the new padding through the button holes, so I gooed the back side with epoxy, and also

put a disc of gasket material under each one to help prevent tearing or pulling through. I didn’t

attach the button lines to the backing discs like they do at the factory. The attaching lines are

crimped to a uniform length. If I do this again, I’ll try doing it that way. I pulled the lines by hand,

and tied them together in pairs, front and back.After some delay, I got back to it. I experimented

with a couple different ways of compressing the pad while I stapled the cover in place. I settled on

clamping the seat between two boards lengthwise, using a rolled up pair of pants to press the

center in a bit more. Once I got it clamped down, it was easy enough to stretch the vinyl with one

hand, and staple with the other. I borrowed the neoprene bushings from my original seat, and reused the pillion bracket from the bike.

Click on any photo for a larger image.

Update

I wasn’t happy with the seat rebuild. I had added new foam over the original foam pad that was on the seat pan when I got it. The

original pad had hardened, and was rounded at the edges. It was better, but not to my liking. I decided to make a slip cover for the

stock seat instead. This would eliminate the expense of replacing all the padding, and I don’t have to deal with removing the

tailbone plate, or the screws from the blind nuts. Much simpler all around. I have most of the materials on hand, and I’ll update as

soon as I put it together.